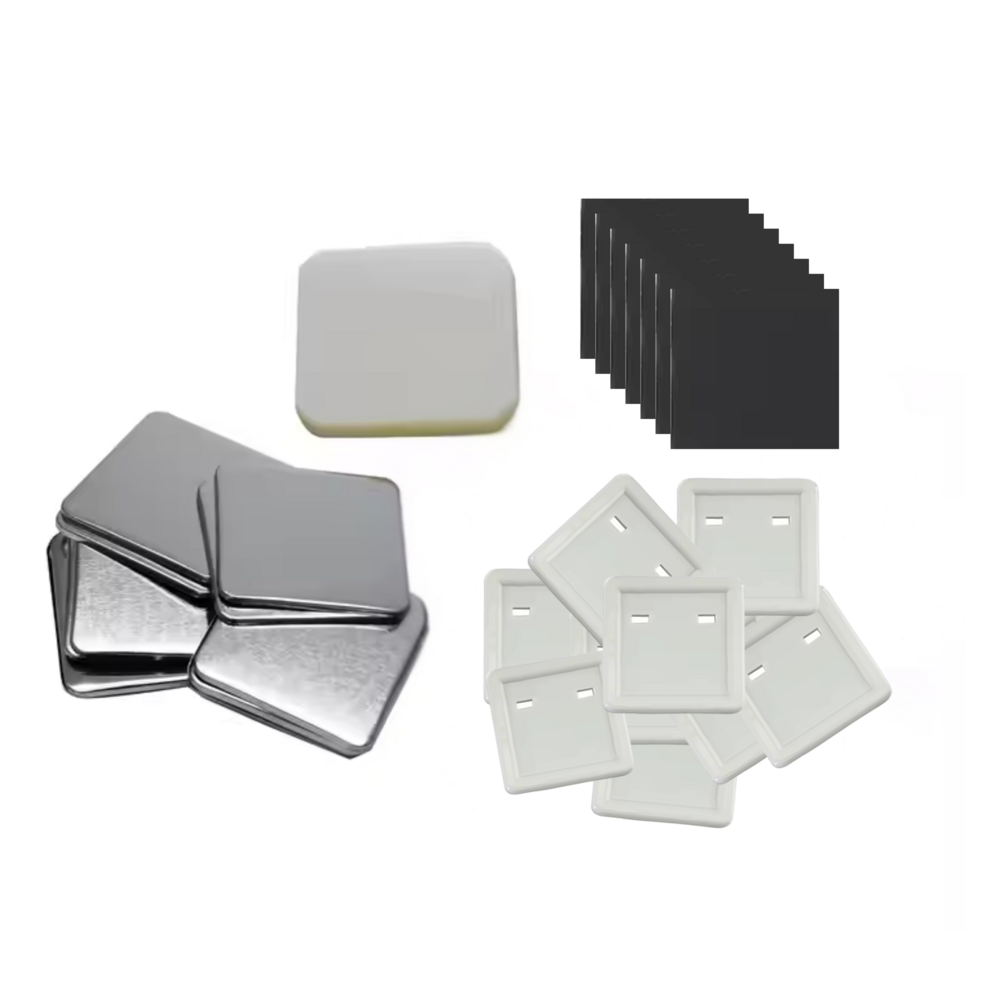

About Button Badge raw material (55*55)

Our premium range of fridge magnet components, includingmaterials for crafting White Button Magnets and Promotional Fridge Magnets, isideal for creating durable, professional-grade magnets for all occasions.Available in various sizes to suit your needs, these materials are perfect forpromotional magnets, event souvenirs, self-printing, and customization.

Eco-Friendly and Resilient MaterialOur button badge raw materials are manufactured using premium, environmentally responsible plastics. This guarantees not only eco-friendliness, but also robust construction suitable for both single-use and repeat applications.

Versatile Application for Various BusinessesWhether you are a manufacturer, wholesaler, exporter or retailer, these button badge components offer flexibility in bulk operations. Their standard size and plain surface make them suitable for printing, branding, or creative designs for a diverse clientele.

FAQ's of Button Badge raw material (55*55):

Q: How are these 55*55 rectangular button badge raw materials typically utilized?

A: These raw materials serve as the base for crafting custom button badges, suitable for personal accessories, business promotions, events, and branding activities. Their plain surface accommodates a variety of prints and designs.

Q: What features make these button badge materials eco-friendly and of good quality?

A: The materials are produced using environmentally responsible plastics, reducing environmental impact. They are engineered for durability, ensuring badges last longer and withstand everyday wear.

Q: When is the best time to source these badge raw materials for bulk manufacturing?

A: It is recommended to procure these materials in advance of high-demand seasons or events, such as festivals, campaigns, or product launches, to ensure a seamless production timeline.

Q: Where are these button badge raw materials available in India?

A: You can obtain these materials from leading dealers, distributors, exporters, importers, manufacturers, retailers, suppliers, traders, and wholesalers throughout India, ensuring widespread accessibility.

Q: What is the process for assembling a button badge with these materials?

A: Assembly typically involves inserting a printed or decorative insert onto the plastic base, securing it with a protective film, and affixing the backing. This process is streamlined for efficient bulk production.

Q: What are the primary benefits of using standard size and shape in badge making?

A: A standard 55*55 mm rectangular size ensures compatibility with most badge-making machines and accessories, simplifying the production and replacement processes for businesses and end users.